MOOS AVC container and pump system

Our specially developed, well-proven AVC system is a direct offshoot of our most important mission: optimising our customers’ efficiency.

Since we launched our first AVC-system over 40 years ago, we have further developed it to produce lots of more compact versions, with volumes ranging from 6 - 42 m³. Demand for the huge advantages offered by this system has been huge, also for smaller tasks that require greater flexibility. A volume reduction of up to 90 percent provides a solid increase in capacity, which the industry has been very keen to take up. The benefits of an AVC system can be seen directly on the bottom line!

Large capacity; large volume reduction

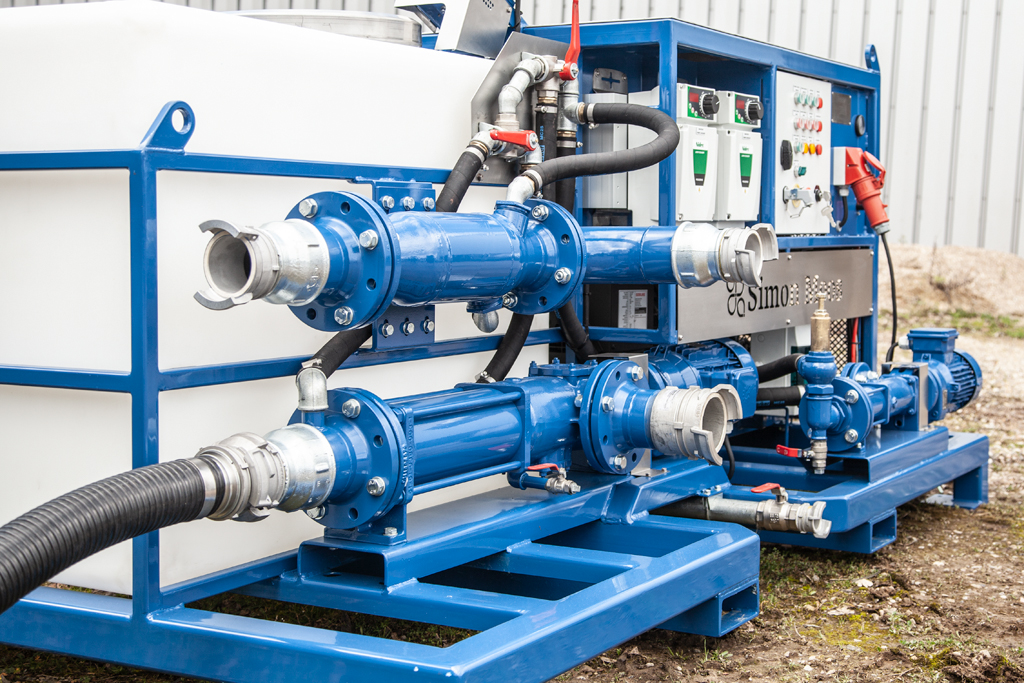

The heart of the AVC system is its on-site separation of sludge into solid waste and water. Using an electrical (EOD) or diesel-powered (DEOD) pump and dosage device, polymer is mixed into the sludge at the same time as it is pumped into the AVC dewatering catchment container. The flocculated sludge is retained inside the dewatering catchment container using special filters, while the water content is directed out of the container via the drain valves. Because sludge generally contains large amounts of water, this process assures volume reduction by up to 90 percent. The AVC can thus, upon repeated fillings, dewater up to 150-200 m³ of sludge before emptying is required.

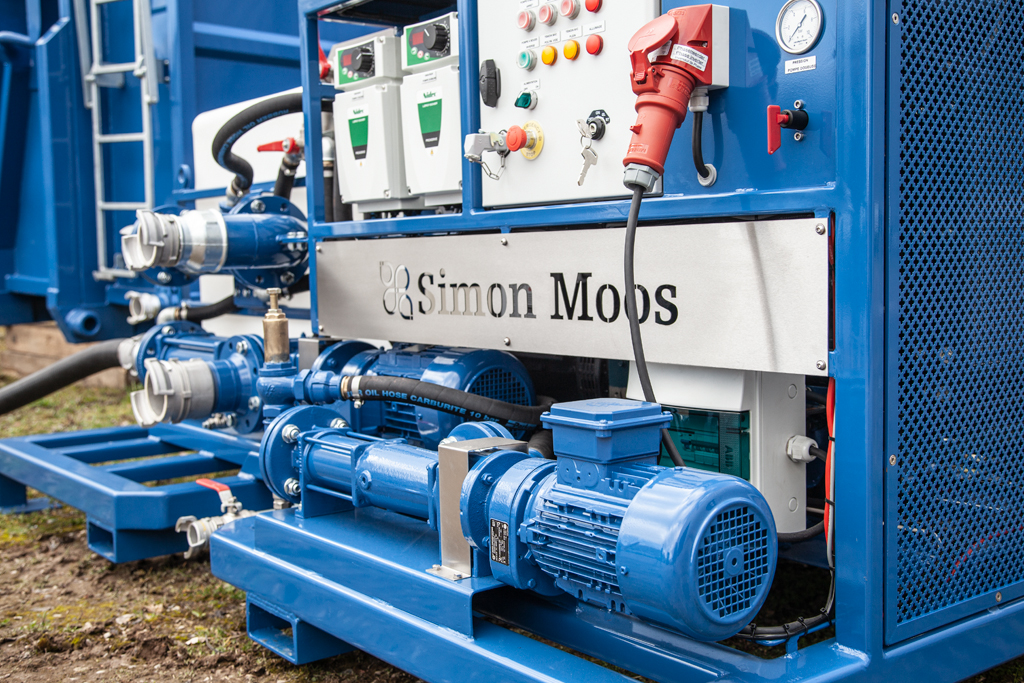

Pump system - electric or diesel

The pump and dosage device is available in two different variants: Electrical (EOD) or diesel-powered (DEOD). The pump and dosage unit makes it easy to regulate polymer quantities and adjust the sludge pump speed, when required.

Factbox

- Up to 90 percent volume reduction.

- Large dewatering capacity.

- High COD and BOD reduction - up to 95 percent.

- Substantially reduced operating costs.

- Low maintenance costs.

- Rapid return on investment.

- Easily operated by a single person.

Video

Moos AVC